ในแวดวงการผลิตสมัยใหม่ ความแม่นยำและความทนทานเป็นเสาหลักแห่งความสำเร็จ ไม่ว่าคุณจะอยู่ในอุตสาหกรร...

หมวดหมู่ข่าว

ผลิตภัณฑ์

โพสต์ล่าสุด

-

ทุกสิ่งที่คุณต้องการทราบเกี่ยวกับการวาดในเชิงลึกที่มีความแม่นยำสูง: คู่มือขั้นสูงสุดของคุณ

Jan 08,2026 -

อ่างล้างจาน RV สแตนเลสทำความสะอาดง่ายหรือไม่?

Jan 01,2026 -

เหตุใดชามดื่มสำหรับสัตว์แบบโลหะจึงเป็นตัวเลือกที่ดีที่สุดสำหรับน้ำดื่มสำหรับสัตว์เลี้ยงที่ปลอดภัย

Dec 23,2025 -

จะทำอย่างไรถ้ามีเสี้ยนปรากฏบนชิ้นส่วนปั๊มขึ้นรูปโลหะ? จะหลีกเลี่ยงได้อย่างไร?

Dec 09,2025 -

ชิ้นส่วนการดัดและเขียนแบบโลหะคืออะไร?

Dec 02,2025

ชิ้นส่วนการดัดและเขียนแบบโลหะคืออะไร?

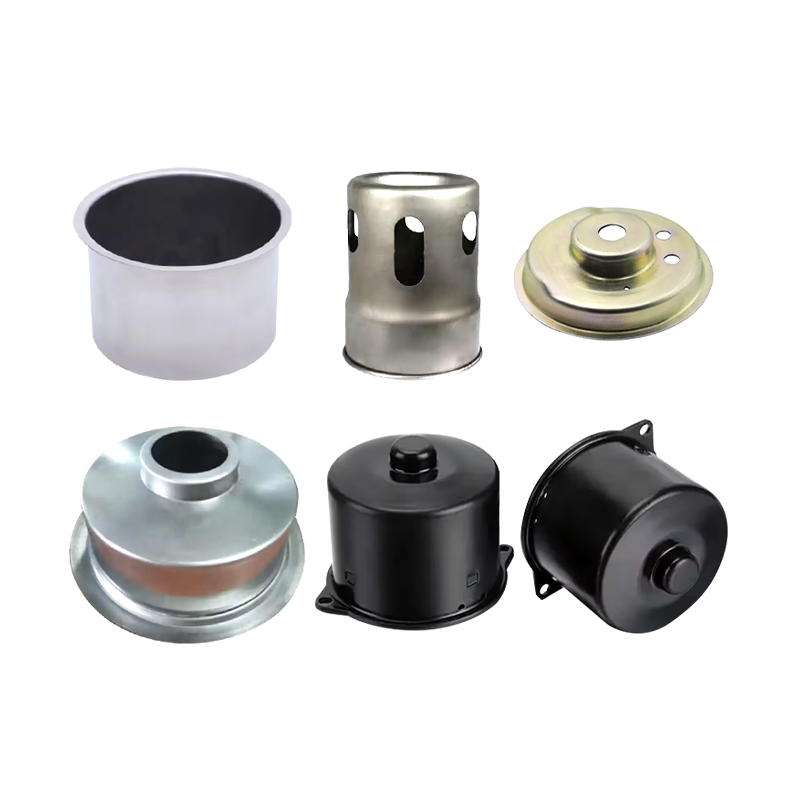

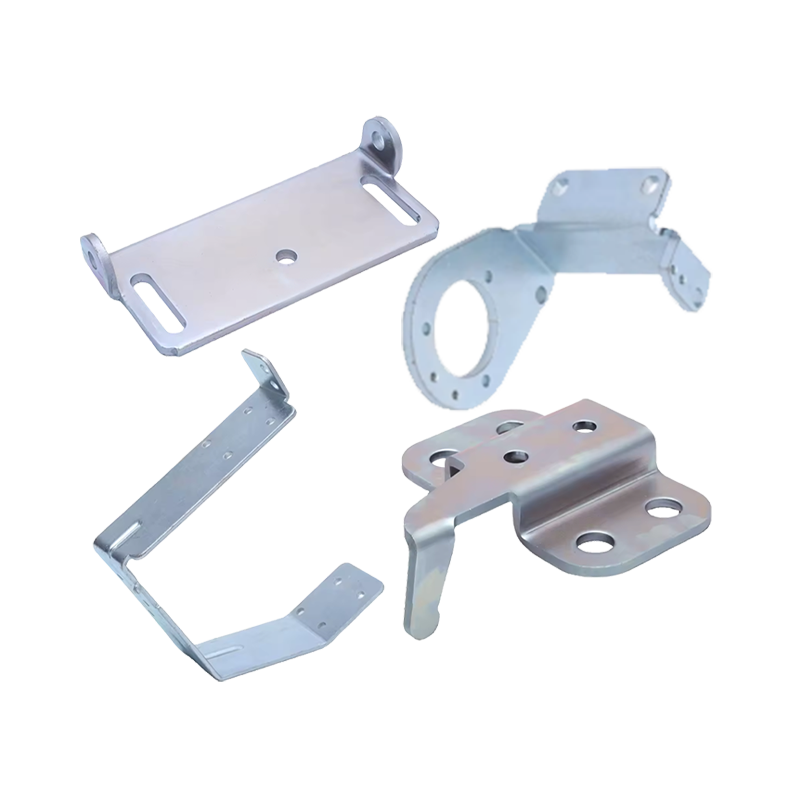

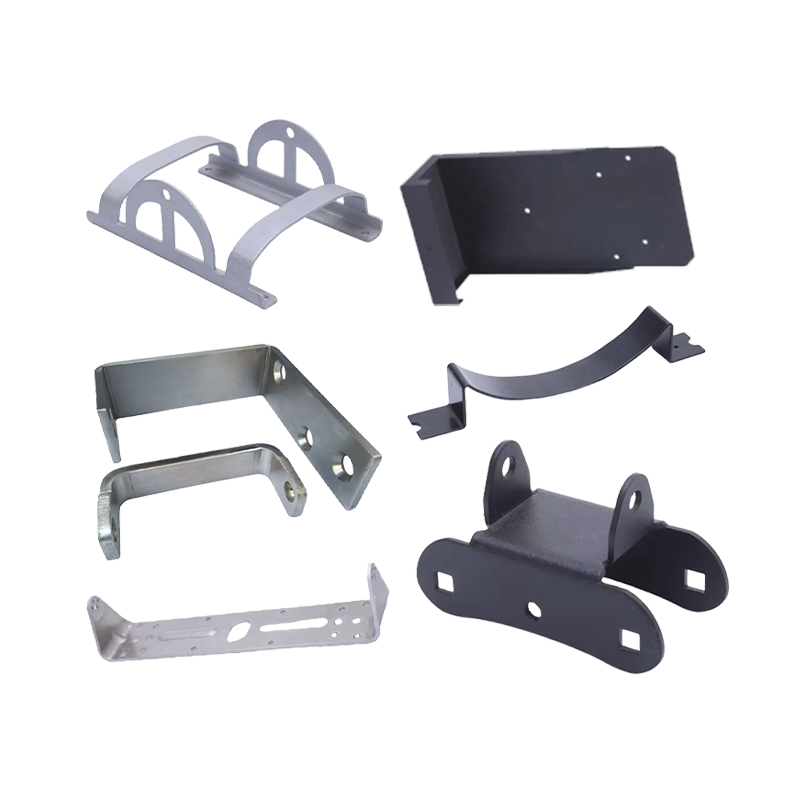

Metal bending and drawing parts are a common type of precision components in manufacturing, widely used in the automotive, aerospace, home appliance, machinery, and electronics industries. The processing of these parts combines metal bending and drawing techniques to achieve the desired shape, strength, and surface finish. Due to their excellent mechanical properties and aesthetically pleasing appearance, metal bending and drawing parts have become core components of many high-end products.

1. What are Metal Bending and Drawing Parts ?

Metal bending and drawing parts refer to parts made from metal materials that have undergone bending and drawing processes to achieve specific shapes, dimensions, and surface finishes. Bending refers to the plastic deformation of metal materials under external force, shaping them into predetermined angles or curves; drawing refers to the mechanical or chemical treatment of the metal surface, giving it a silk-like texture.

These parts not only require good geometric shape and dimensional accuracy but also excellent surface finish to meet the dual requirements of appearance and function in different fields.

2. Processing Technology of Bending and Drawing Metal Parts

The processing technology of bending and drawing metal parts mainly includes two processes: metal bending and wire drawing.

Metal Bending

Metal bending is a common plastic deformation process, mainly using external force to bend metal materials into the desired shape in a cold or hot state. Metal bending is widely used in the manufacture of various metal parts, especially in the processing of sheet metal, pipes, and profiles.

Common metal bending methods include

Stamping Bending:Pressing metal sheets into the desired angle or curve using dies and punches.

Rolling Bending:Continuously bending metal using rollers and tubes, suitable for large-scale production.

Bending:Bending metal sheets using mechanical bending machines, suitable for small to medium batch production.

Wire Drawing

Wire drawing is a surface treatment process, typically used for the appearance modification and performance enhancement of metal materials. The wire drawing process mainly uses mechanical equipment to rub the metal surface against materials such as sandpaper, brush bristles, and abrasives, thereby forming a uniform fine wire texture. Brushing not only enhances the aesthetics of metal surfaces but also improves their corrosion resistance and wear resistance.

Common brushing methods include

Mechanical Brushing:Using a brushing machine to continuously grind the metal surface to create a fine brushed texture.

Chemical Brushing:Forming specific textures on the metal surface through a chemical reaction; commonly used for materials such as stainless steel and aluminum alloys.

Electrolytic Brushing:Creating a brushed effect on the metal surface through the action of electric current and an electrolyte; suitable for certain alloy materials.

3. Characteristics of Metal Bending and Drawing Parts

High Strength and Durability

Metal parts that have undergone bending and drawing typically possess high strength and durability. The bending process enhances the material's mechanical properties through plastic deformation, while the drawing process improves surface corrosion resistance and wear resistance, extending the part's service life.

Beautiful Appearance

The drawing process gives metal parts a unique surface texture, making them more aesthetically pleasing. A finely drawn effect not only increases the visual appeal of the part but also conceals minor surface imperfections, enhancing the overall quality of the product.

Good Dimensional Accuracy and Stability

Modern processing equipment and precision technology ensure high precision and stability in the metal bending and drawing process. This makes metal bending and drawing parts suitable for industries with high precision requirements, such as electronics, automotive, and aerospace.

4. Application Areas of Metal Bending and Drawing Parts

Metal bending and drawing parts are widely used in various industries, especially in areas requiring high strength, aesthetic appearance, and excellent performance, where they possess irreplaceable advantages.

Key application areas include:Automotive Industry:In the automotive industry, bent and brushed metal parts are commonly used to manufacture exterior trim, interior components, and structural parts. For example, brushed metal panels and trim strips are widely used in door panels, window frames, and dashboards, improving both the appearance and corrosion resistance of the vehicle.

Electronics Industry:The application of bent and brushed metal parts in electronic products is also becoming increasingly common. For example, the casings, brackets, and structural components of devices such as smartphones, televisions, and computers often utilize bent and brushed metal parts. The brushing process gives these parts not only high strength but also a modern appearance.

Home Appliance Industry: In the home appliance industry, bent and brushed metal parts are widely used in the external casings and internal structural components of appliances such as refrigerators, washing machines, and microwave ovens. The brushed surface treatment improves the oxidation resistance and durability of the parts, while also enhancing the product's appearance and feel.

Aerospace Industry:In the aerospace field, bent and brushed metal parts are frequently used to manufacture critical structural components for aircraft, rockets, and satellites. These parts typically require extremely high strength, corrosion resistance, and precision, and metal bending and drawing processes can meet these stringent requirements.

Metal bending and drawing parts are widely used in various industries due to their excellent mechanical properties, durability, and aesthetically pleasing appearance. With the continuous development of manufacturing technology, metal bending and drawing processes will become increasingly precise and efficient, providing more innovative solutions for various industries.

จะทำอย่างไรถ้ามีเสี้ยนปรากฏบนชิ้นส่วนปั๊มขึ้นรูปโลหะ? จะหลีกเลี่ยงได้อย่างไร?

คู่มือการเลือกชามใส่น้ำหมูสแตนเลส 304: การแบ่งย่อยความต้านทานการกัดกร่อนและประเด็นสำคัญที่ทำความสะอาดง่ายอย่างครอบคลุม

สินค้าที่เกี่ยวข้อง

ไม่ว่าคุณต้องการเป็นพันธมิตรของเราหรือต้องการคำแนะนำอย่างมืออาชีพหรือการสนับสนุนในการเลือกผลิตภัณฑ์และการแก้ปัญหา ผู้เชี่ยวชาญของเราพร้อมเสมอที่จะช่วยเหลือภายใน 12 ชั่วโมงทั่วโลก

ติดต่อเราPhone:+86 139-5824-9488

FAX :+86 574-86150176

E-mail: [email protected] [email protected]

Address: หน่วยที่ 2 อาคาร 19 สวน Zhichuangzhizao เขตอุตสาหกรรมเฉิงตง เซียงซาน หนิงโป 315705 เจ้อเจียง จีน

สำหรับผู้ที่ชื่นชอบรถ RV พื้นที่ห้องครัวมีจำกัด วัสดุและความง่ายในการทำความสะอาดอ่างล้างจานส่งผลโ...

ด้วยความตระหนักรู้เกี่ยวกับการดูแลสัตว์เลี้ยงเพิ่มมากขึ้น เจ้าของสัตว์เลี้ยงจึงให้ความสำคัญกับสภา...